Background

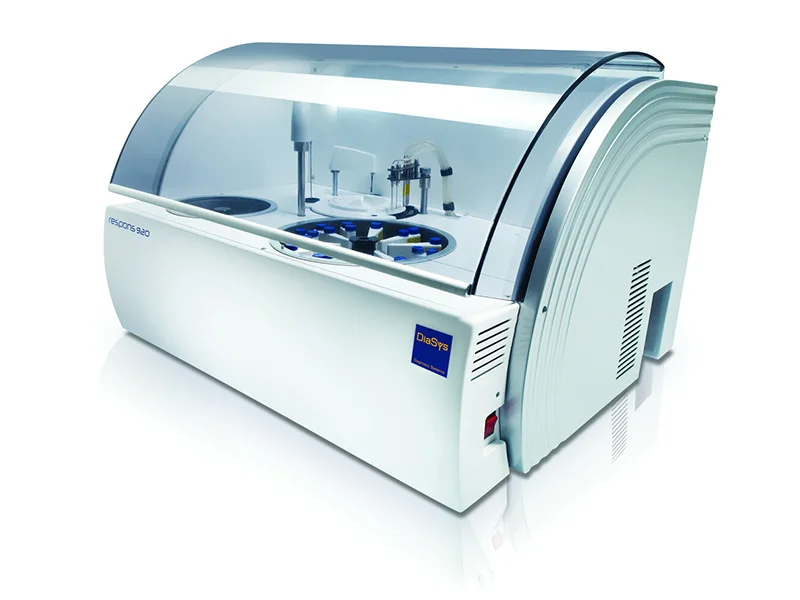

An European developer of high-quality diagnostic systems, needed a reliable cooling solution for their temperature-sensitive chemical testing reagents, which must be stored at 4-8℃. Their current chiller from a competitive supplier lacked sufficient cooling capacity, certifications, and had condensation issues.

Challenges

The medical OEM’s instruments are compact, limiting space for cooling devices. Traditional units often have

reduced cooling capacity due to size constraints. The medical OEM required a new chiller that:

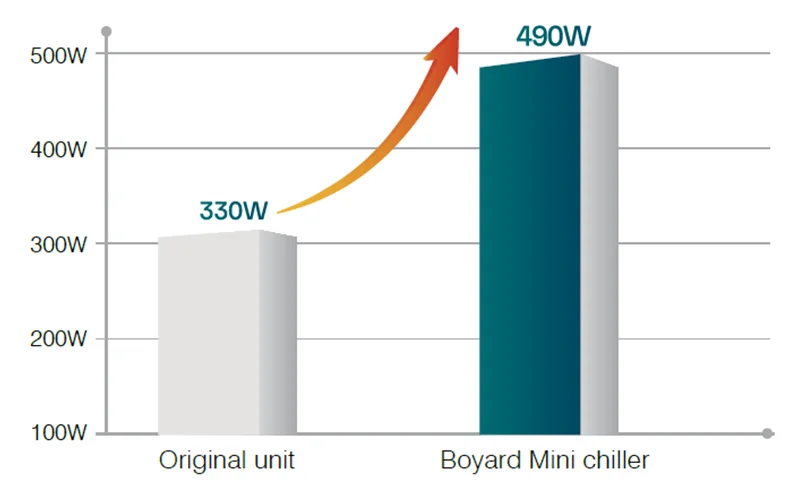

- Increased cooling capacity to at least 450W

- Had international certifications

- Used R290 refrigerant with low global warming potential (GWP)

- Solved condensation issues

Solution

Boyard collaborated with the medical OEM to understand the project details, such as coolant circulation volume, initial temperature, target temperature, and cooling time. Boyard designed the BYL030PDC24 mini-chiller, increasing compressor displacement from 2.0cc to 3.0cc, boosting cooling capacity by 50%. Boyard also replaced the capillary tube with an expansion valve to address condensation.

Results