In the pursuit of optimal cooling performance, energy savings, and operational stability, what sets inverter refrigeration units apart from their conventional on-off counterparts? Beyond basic function, the differences lie in how they respond to real-world conditions. The following analysis contrasts these two systems across fundamental performance criteria, revealing why inverter units are increasingly becoming the standard for efficient and precise temperature management.

Energy Efficiency:

Inverter Unit: Their core advantage lies in their extremely high efficiency under partial load conditions. Most refrigeration systems operate under partial load for over 90% of their runtime. Variable frequency compressors achieve infinite speed regulation (e.g., 30 to 80 Hz), allowing cooling output to precisely match real-time thermal load. This not only avoids the energy waste of “a large horse pulling a small cart” but also eliminates losses from frequent start-stops. In actual operation, they save an average of 25%-30% energy, with particularly significant effects in scenarios with large load fluctuations.

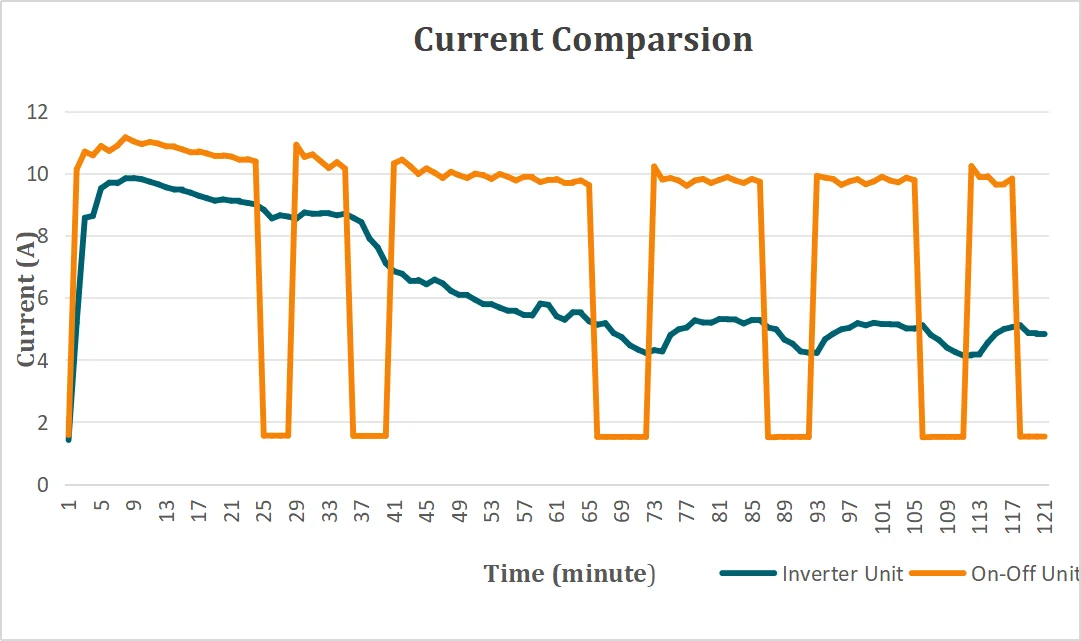

On-Off Unit: They operate on an “ON-OFF” mode. When the temperature reaches the set point, the compressor stops completely; when the temperature rises again, the compressor starts at full power. During periods of low load demand, this “start-stop-start” cycle itself consumes a significant amount of ineffective work (especially the high inrush starting current; establishing the refrigeration cycle requires additional power consumption). This leads to a sharp drop in system efficiency during partial load operation (during frequent cycling).

The current of the inverter unit is more stable, and the peak current is lower

Temperature Control:

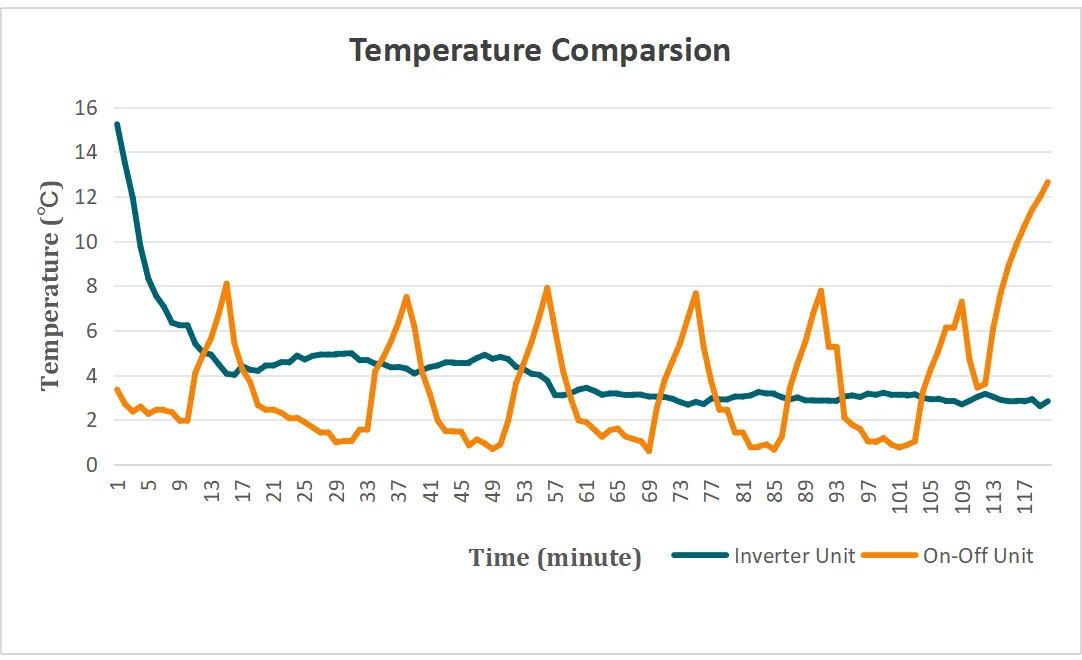

Inverter Unit: By adjusting speed to compensate for heat ingress, they can control cold storage or process temperatures within a range of ±1°C or even narrower. This stable, precise control is crucial for high-end cold chain scenarios, effectively ensuring product quality and process stability.

On-Off Unit: Temperature control relies on compressor cycling, which inevitably results in a periodic temperature fluctuation curve (e.g., set to 2°C, but actually cycles between 1°C and 7°C). This fluctuation can affect food preservation periods, increase product moisture loss, and subject stored items to repeated thermal shock.

More stable temperatuer control

Operating Noise:

Inverter Unit: During periods of low load demand (e.g., at night, in winter), the compressor can operate at low speeds quietly, reducing overall noise levels by 5-10 decibels. This is a significant advantage in noise-sensitive environments like residential areas, hotels, high-end supermarkets, and offices.

On-Off Unit: When operating, the compressor runs at a fixed high speed (e.g., 3000 RPM), producing consistent and relatively high noise levels, with no ability to adjust based on environmental needs.

Load Variation Adaptation:

Inverter Unit: Similar to a car’s “continuously variable transmission,” cooling output can be adjusted linearly and infinitely from 20% to 100%. Regardless of how dramatically the load changes (e.g., goods entering a cold room, people entering/exiting), the system can respond by smoothly adjusting its speed, maintaining stable system operating parameters (cold room temperature), which is highly beneficial for long-term system health. It allows adjustment of evaporation temperature, making it suitable for multiple cold cabinets or rooms, with rapid response to changing refrigeration loads.

On-Off Unit: Similar to a car that only has “full throttle” and “ignition off” states, their only response to changing loads is to cycle on or off. This leads to frequent, large fluctuations in system pressure, which is detrimental to stable operation.

Ambient Temperature Adaptability:

Inverter Unit: With advanced control logic and wide-frequency operation capability, they can operate stably within a broader ambient temperature range (e.g., -30°C to 50°C). In low-temperature environments, they can maintain sufficient condensing pressure by adjusting DC fans to ensure normal system operation; in high-temperature environments, they can also prevent high-pressure shutdowns in the refrigeration system through optimized control.

On-Off Unit: They have poorer adaptability to ambient temperatures. In low winter temperatures, excessively low condensing pressure may prevent the system from establishing a normal high-low pressure differential, hindering refrigerant flow and even triggering low-pressure shutdowns, often requiring additional installation of a “condensing pressure regulating valve.” In high summer temperatures, excessively high condensing pressure can easily lead to compressor overheating, increased power consumption, and even high-pressure shutdowns.

Start-Stop Frequency and System Reliability:

Inverter Unit: They feature soft starts with smooth current rise, causing minimal impact on the power grid and motor. During operation, start-stops are almost unnecessary, as the compressor runs smoothly under low mechanical stress. This significantly reduces the start-stop stress on mechanical components, lowering wear and failure rates, while also avoiding energy losses from frequent cycling. Especially during low-speed operation, they efficiently match load demand, reducing energy waste.

On-Off Unit: They may experience hundreds of hard starts per day. Each start’s inrush current generates significant electromagnetic and thermal stress. Frequent impact load changes accelerate compressor wear and can lead to poor oil return, which are major causes of system failures (e.g., motor burnout, compressor wear).

Additional Value of Inverter Units:

Lower Long-Term Costs

Although the initial investment is 15%~30% higher, the energy savings can offset the price difference within a 6 month payback period.

Intelligent Integration

It supports the Modbus protocol, facilitating easy integration with Building Automation Systems (BAS).

Capabilities include remote monitoring, fault early warning, and energy efficiency analysis.