Why Compressors Are Indispensable for Refrigerated Displays

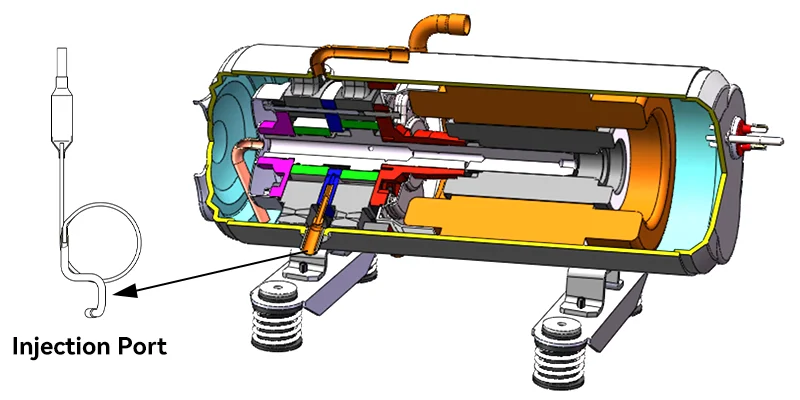

Refrigeration systems rely on compressors to act as the “heartbeat,” circulating refrigerant and regulating temperatures. Traditional reciprocating compressors often struggle with energy waste, temperature fluctuations,and noise—issues that rotary compressors eliminate through innovative engineering.

Energy Efficiency That Cuts Costs

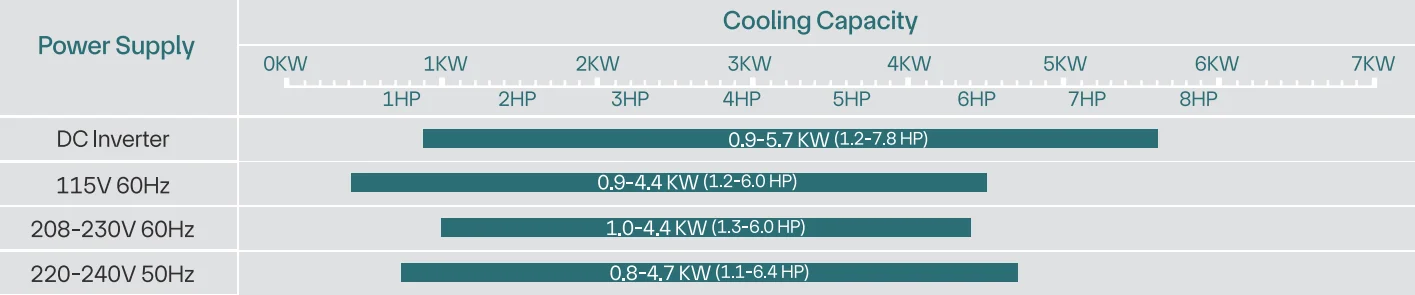

Modern rotary compressors use variable-speed technology to adjust power output in real time. Unlike fixed-speed models that run at full capacity regardless of demand, these systems consume up to 30% less energy, saving retailers thousands annually. For example, a supermarket operating 12 hours a day can reduce energy bills by $1,500 yearly per display case.

Temperature Stability for Product Integrity

Fluctuating temperatures can spoil perishables in minutes. Rotary compressors maintain ±0.5℃ precision, even during peak foot traffic or door openings. In frozen food sections, specialized compressors operate at -30℃ to keep ice cream and seafood at optimal quality without energy spikes.

Silent Operation for Customer Comfort

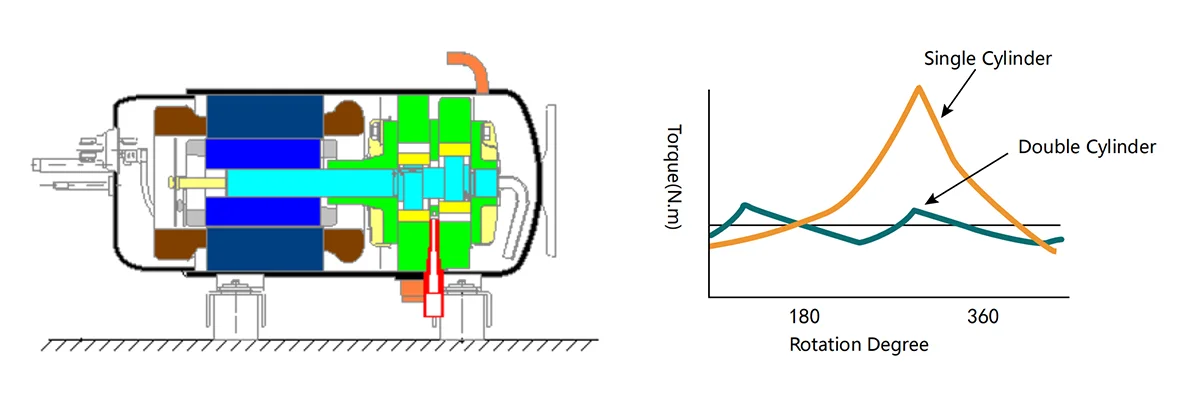

In retail environments, noise is a distraction. Rotary compressors operate at 55~65dB—quieter than a typical conversation—making them ideal for supermarkets, showrooms, and hotels.With two rotors distributed in the 180° opposite direction of one crankshaft, the start and running torque of the compressor is small, so the operation is more stable.  Compact Size and Larger Display Volume

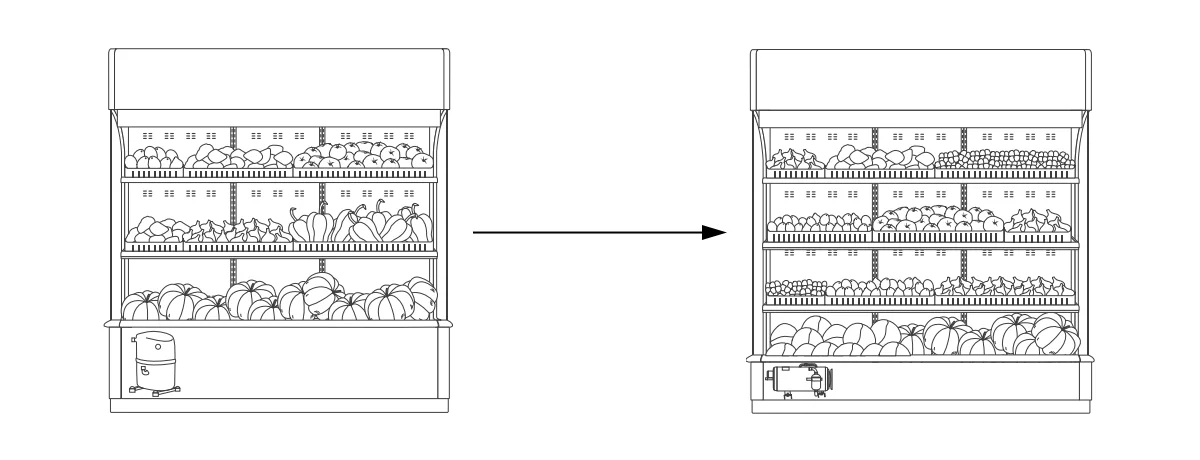

Compact Size and Larger Display Volume

Horizontal design with lower height can increase the storage room