Outdoor Remote Condensing Units

Outdoor Remote Condensing Units

A remote refrigeration unit, also known as an outdoor refrigeration unit, is a specialized type of refrigeration system commonly used in commercial and industrial applications.Remote refrigerators are insulated cold food storage areas that are outfitted with an evaporator inside, but the compressor and condenser are located in a remote area away from the refrigerator itself.

Advantages of remote refrigeration unit

Features of Boyard outdoor units

1.The unit use medium and low temperature compressor ;

2.The ambient temp, range for the unit working from -20~-48℃ ;

3.The unit use Optimized Internal thread condenser can reduce refrigerant charging ;

4.All models equipped with microcomputer control board, sight glass and AC contactor;

5.Fixed speed units and variable frequency units,Horsepower covers 1~12HP;

6.Support differentiated customization; Compressor requirements met includes Boyard ,Copeland,Hitachi,etc

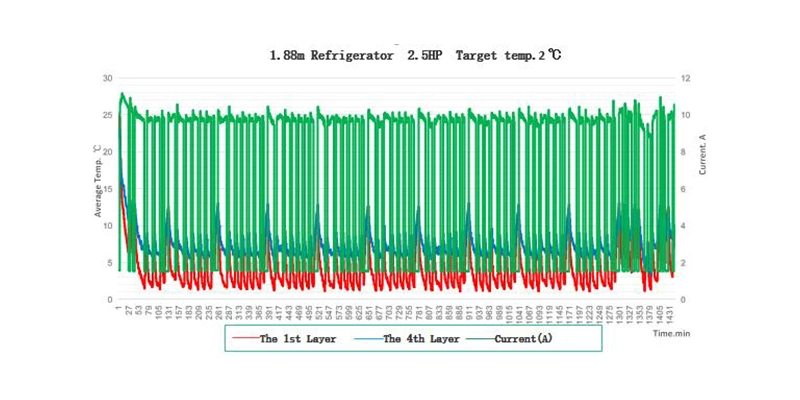

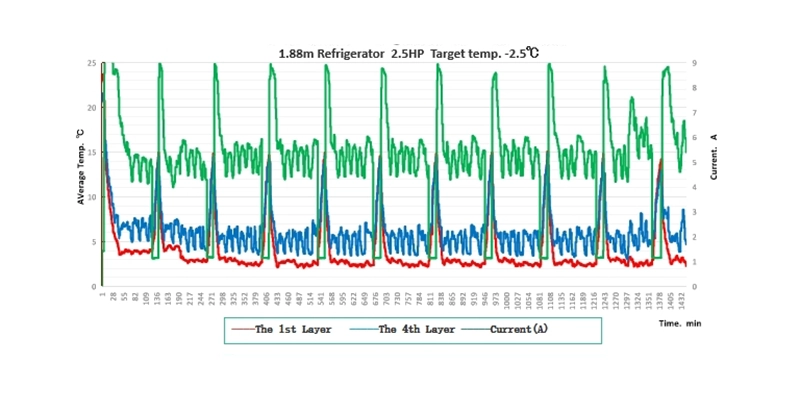

Comparison of fixed frequency and variable frequency units

The starting frequency of a fixed frequency compressor is much higher than that of a variable frequency compressor. Every time the compressor starts, it consumes a lot of electricity. However, variable frequency compressors are more intelligent and have more precise temperature control, so the compressor does not start frequently, which makes it more energy-efficient. Generally, it can save 10% to 35% energy, and the amount of energy saved depends on the working conditions of the compressor and the setting of the frequency converter parameters.

Power supply

E-220V 50Hz、Y-220V 60Hz、M-380V 50Hz、Z-Frequency conversion

Regular maintenance of the unit

- Before inspection and maintenance, the power supply should be cut off and the power plug should be pulled out of the socket.

- After the outdoor unit is used for a long time, dust will be attached to the heat ex-changer, which will reduce the heat transfer effect and reduce the cooling capacity of the unit, and clean the outdoor heat ex-changer.It should be cleaned at least once every two months, with a long-bristled brush, or with compressed air to blow off the surface of the outdoor heat ex-changer, and do not wash with tap water.

- Regularly observe the running sound of the unit, and if there is any abnormality, please contact professionals in time for troubleshooting.