Background

The global leader of vehicle air conditioners spacialized in designing and manufacturing roof-top A/C units for caravans and recreational vehicles (RVs).

In recent years, the demand for recreational vehicles (RVs) has grown significantly as consumers spend more time outdoors or traveling as ‘nomads.’ These RVs are often equipped with advanced technology, such as solar-powered air conditioners and hot water generators, to provide maximum comfort and convenience for passengers regardless of outdoor conditions.

Traditionally, RV air conditioning units had used basic single-cylinder, fixed-speed compressors to keep the unit cost competitive against other A/C OEMs. However, with increasing demand for energy conservation and environmental preservation, single-cylinder compressors can no longer meet the market’s demand due to its limited capability.

The OEM, the global leader of RV A/C units, turned to Boyard for energy-efficient and quiet compressors for their next-generation A/C units.

Challenges

Therefore, in the new generation of their A/C unit, the OEM set the following requirements:

- Deploy compressors with high COP for higher energy savings

- Reduce noise and vibration to increase comfort for passengers

- Increase reliability and reduce the failure rate of the A/C unit

Solution

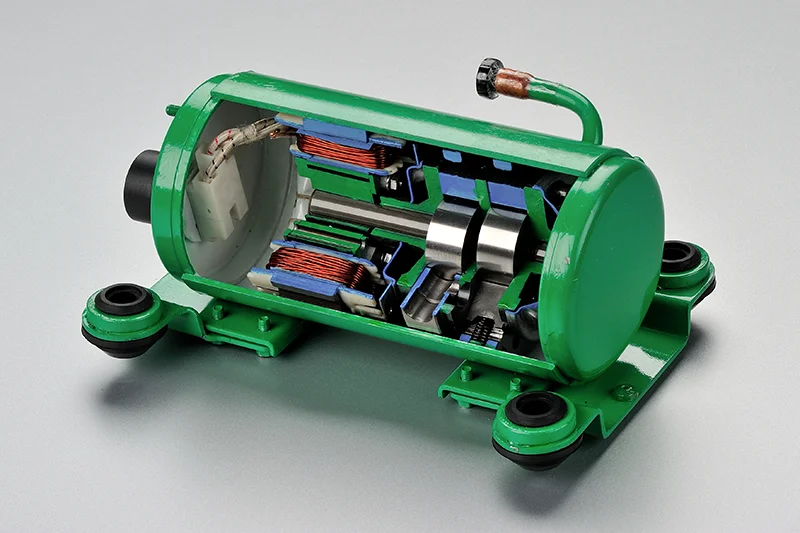

Boyard collaborated with the OEM to develop a new horizontal, variable-frequency compressor with dual cylinders. The new JFSA116Z220 compressor met the OEM’s requirements to stay abreast of RV market demand. This variable-speed technology automatically adjusts the compressor’s operating frequency on demand, avoiding unnecessary energy waste and meeting the requirements for energy efficiency and reduced noise and vibration.