Rotary compressors have an annual production output of nearly 200 million units, which can be categorized into vertical and horizontal types based on their shape. Approximately 99% are vertical compressors, while the remaining 1%, equivalent to 2 million units, are horizontal compressors.

Why is there such a significant difference in the numbers between vertical and horizontal compressors?

This disparity is related to application scenarios and costs. Vertical rotary compressors have lower manufacturing costs and are widely used in household air conditioning and heat pumps, which typically employ outdoor split unit designs. These designs provide sufficient height in the unit, allowing for the use of the more cost-effective vertical compressors. In contrast, horizontal compressors are often utilized in specialized scenarios where space height is a critical factor, mostly falling into niche markets, where each individual market’s scale is far smaller than that of household air conditioning.

| Aspects | Vertical compressor | Horizontal compressor |

| Market size | ★★★★★ | ★ |

| Manufacturing cost advantage | ★★★★★ | ★★★ |

| Design complexity | ★★★ | ★★★★★ |

| Supply chain maturity | ★★★★★ | ★★★ |

| Footprint | ★★★★★ | ★★ |

| Occupancy Height | ★ | ★★★★★ |

| Manufacturing process | ★★ | ★★★★ |

The core value of horizontal compressors lies in their compact vertical profile. For compressors with equivalent cooling capacities, such as the Boyard compressor, horizontal type typically achieve 40-60% height reduction compared to vertical. The larger the displacement, the more pronounced the height advantage of horizontal compressors becomes.

The core value of horizontal compressors lies in their compact vertical profile. For compressors with equivalent cooling capacities, such as the Boyard compressor, horizontal type typically achieve 40-60% height reduction compared to vertical. The larger the displacement, the more pronounced the height advantage of horizontal compressors becomes.

Under equivalent cooling capacity, a height comparison between Tecumseh reciprocating compressor and Boyard horizontal compressor:

| Tecumseh Model | Dispalcement (cc) | Height(mm) | Boyard Model | Height(mm) | Percentage Reduction in Height |

| AE2430Z | 14.5 | 197 | QHD-13K | 185 | 6% |

| CAJ2464Z | 34.5 | 280 | QHD-23K | 195 | 30% |

| FH4524Z | 43.3 | 354 | QHD-36K | 195 | 45% |

| FH2480Z | 53.2 | 370 | THSD456KS | 195 | 47% |

Height Advantages of Horizontal Rotary Compressor in Multiple Applications:

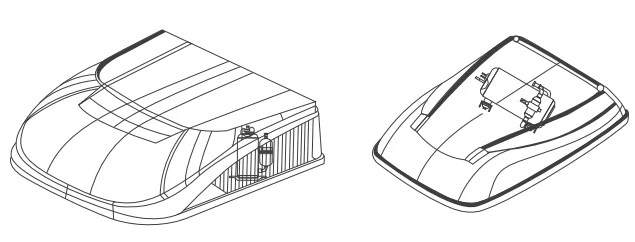

1.Vehicle Air Conditioning (e.g., Truck Parking Coolers, Caravan Air Conditioners)

a) Low height enhances vehicle clearance and maneuverability.

b) Low height reduces aerodynamic drag and improves aesthetic appeal.

c) The low center of gravity provided by the horizontal design improves driving stability and comfort.  2.Commercial refrigeration,Under equivalent cooling capacity conditions

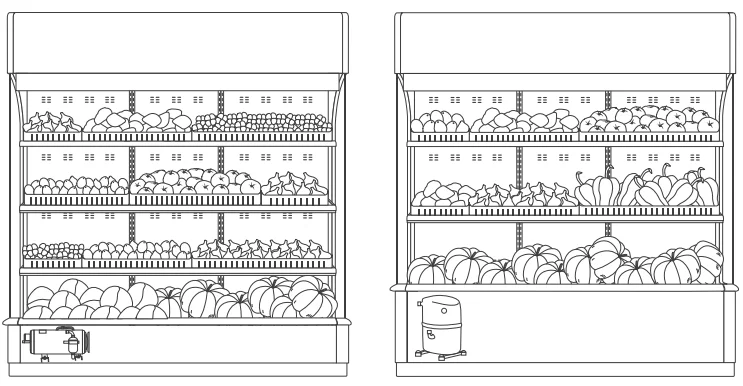

2.Commercial refrigeration,Under equivalent cooling capacity conditions

a) Plug-in cabinet: The reduced height of the horizontal compressor maximizes product display space.

b) Top mounted monoblock((commonly used in cold room): The horizontal compressor reduces overall height of the system .  3.Roof-mounted household system

3.Roof-mounted household system

a) Chiller, water sourced heat pump for apartment: The system is installed on the ceiling, with minimized height to maximize headroom for occupants.

b) Similar applications include ceiling-mounted dehumidifiers (e.g., MVH).

Design Challenges of Horizontal Compressors:

- Gravity Impact on Components:When laid down, the crankshaft and pump parts face longitudinal gravity impacts, which necessitate high design standards for dynamic balance and wear resistance, ensuring uniform distribution of axial and radial forces to avoid uneven wear.

- Thermal Management:Optimizing airflow and maintaining thermal balance in a horizontal layout can be challenging.

- Oil Supply:Unlike vertical compressors, where gravity naturally maintains oil at the bottom for continuous lubrication, horizontal compressors face gravity-induced challenges. A dedicated design is required to establish two pressure-differential chambers, ensuring stable oil supply via pressure differentials. Additionally, specialized oil supply structures must be integrated at multiple components within the pump body.

Manufacturing Challenges of Horizontal Compressors:

- Low Material Universality: Since horizontal compressors represent about 1% of total rotary production and cater to niche markets, there are many model types to meet market demands. The commonality of components is low, often resulting in higher procurement costs.

- Complex Manufacturing Processes: To address the technical challenges of these compressors, horizontal designs incorporate unique specifications, leading to a greater number of parts than vertical compressors, with more complex manufacturing processes. Additionally, the typically side-mounted intake and exhaust passages of horizontal compressors create difficulties for mechanical jaws during processing, resulting in lower automation levels and higher manufacturing costs. A series of custom fixtures and tooling must also be designed.

Boyard’s Expertise in Horizontal Rotary Compressors: A Niche Leader in Space-Saving Solutions

Boyard has been dedicated to manufacturing horizontal rotary compressors for 20 years. The concept of horizontal rotary compressors originated in Japan in the last century; however, as China’s manufacturing capabilities have increased and costs have become more prominent, the manufacturing and design center of these compressors has gradually shifted from Japan to China in recent years. Throughout this process, Boyard has focused on independent R&D for horizontal rotary compressors, overcoming numerous challenges to produce its first horizontal rotary compressor in 2006, utilized in RV air conditioning. In recent years, we successfully developed and mass-produced more challenging horizontal low-temperature refrigeration and freezing compressors (MBP & LBP Compressor). With the electrification of vehicle air conditioning, we developed the first generation of 24V DC horizontal compressors in 2013. In 2017, we introduced the first generation of 312V dual-rotary DC horizontal compressors for use in RV air conditioning. Throughout this process, Boyard has led the market with technological innovation.

Among numerous rotary compressor manufacturers, Boyard is the most focused company on horizontal compressors, with more than 60% of its production dedicated to these units, whereas other manufacturers have horizontal compressor proportions generally below 1%.

Through decades of focused R&D, Boyard has built a robust technical foundation in horizontal rotary compressor design, complemented by:

- Established manufacturing capabilities: Optimized processes, stable supply chains, and a comprehensive product lineup covering diverse applications.

- Proprietary innovations: Custom tooling, dual-pressure chamber oiling systems, and advanced thermal management solutions.

- Market-driven R&D: A vertically integrated platform enabling rapid adaptation to emerging needs, from energy-efficient refrigeration to next-generation electrified mobility.